The U.S. Department of Energy announced today the Waste Treatment and Immobilization Plant at Hanford has produced the first container of clean glass as workers commission the first of two large melters in the plant’s Low-Activity Waste Facility.

“With the first container of clean glass produced, we are entering the next era of risk reduction in the Hanford environmental cleanup mission as we work towards the start of tank waste immobilization,” said Hanford Site Manager Brian Vance. “This achievement represents a significant step towards a cleaner and more sustainable future. We are excited about the positive impact this project will have on our community and the environment, and we remain committed to our mission.”

Earlier this year, the Department and its contractor, Bechtel National, Inc., finished heating up the first of two melters in the Waste Treatment and Immobilization Plant’s Low-Activity Waste Facility. The melters will transform Hanford radioactive and chemical tank waste into a vitrified glass form safe for disposal.

“We are honored to celebrate this milestone. It stands as a testament to the unwavering dedication and the hard work of our incredible partners and team,” said Brian Hartman, Bechtel Senior Vice President and Project Director of the Hanford Vit Plant.

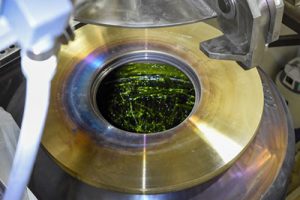

In August, the Department and Bechtel started making glass after workers poured the first batches of glass beads, called frit, into the melter. By early September, the first molten pool of glass was created in a commissioning process that led to filling the first container with clean glass recently at the plant. This is a major step toward future immobilization of low-activity tank waste from Hanford’s underground tanks in a glass form for disposal.

“Turning tank waste into robust and stable glass for final disposal is paramount to the protection of the Columbia River and the Pacific Northwest. Today we celebrate Energy completing the first test glass made by a state-of-the-art melter – the largest of its kind in the world,” said Suzanne Dahl, Tank Waste Treatment section manager with the Washington Department of Ecology’s Nuclear Waste Program. “We look forward to completion of additional testing, and finally to vitrification of actual tank waste. Thanks to Energy and its contractors for our productive partnership involving the permitting and construction of this crucial facility.”